Dock Board Model T (2 Pin)

Bridging Gap Between Dock And Trailer

|

|

Model PricingDimensionsSelection GuideFAQ

The heavy-duty steel dock board, Model T, from Bluff is held in position using two 1" stress-proof steel pins. When properly placed in the side pocket insertion holes, these pins hold the dock board firmly in place guarding against slippage. Simply select the proper pin hole location for use with conventional, refrigerated, or container trailers, you can also turn the dock board around for below dock conditions.

- American Manufactured

- All welded ANSI Rated steel construction

- Two four-hole pin pockets placed on each edge

- Adjustable lip to handle both Reefer and Dry Van Trailers

- Fold down lifting loops

- Double-bend design

- Made to Order Options

- Common sizes stocked

- Stock to 7 days

|

Give Our Dock Board Experts A Call

1800-741-1258

Note: For applications where trailers are parked at an extreme angle or are farther than 11" from the dock a 4 Pin Model C dock board is necessary to safely bridge the gap. Navigate to 4 Pin Model C

Don't see the size you need?

Give us a call at 1800-741-1258

|

|

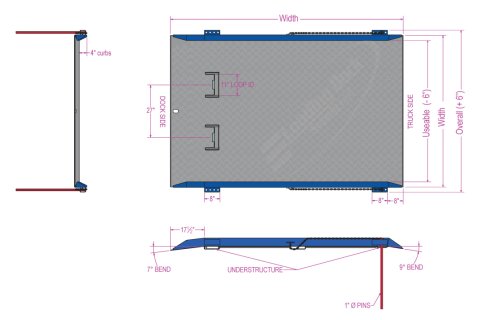

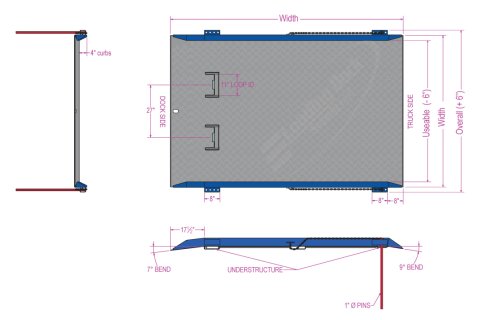

Overall Width: +6"

Usable Width: -6"

Curb Height: 4"

Curb Width: 3"

Pin Length: Varies by board length

Brochure (PDF)

|

|

| |

|

- Forklift Cutouts to scoop the board up

Speed up the loading process with the Speedy Board® style Dock Board. Designed to be scooped up, the speedy board cutouts in the leading edge of the lip eliminate the need to climb down from the forklift to prepare a dock board for movement. The cutouts are available on the TFL, TNB, SC, and all aluminum dock boards or plates at no additional charge.

Notes: This dock board style is intended for above dock loading applications.

|

|

| |

|

- Single bend instead of two

- Full width Leg

- Lifting Chains in place of forklift loops

- (Optional) eliminate the need for a chain with Speedy Board Cutouts

Intended for above dock loading applications only, the TNB model dock board offers design elements similiar to our Aluminum Dock Board line except with added capacities only steel can offer.

Notes: This dock board style is intended for above dock loading applications.

|

|

| |

|

- Steel Legs in place of locking pins

- Forklift loops

The model TFL dock board offers all the design elements of a Model T Dock Board with the exception of legs in lieu of steel locking pins.

Notes: This dock board style is intended for above dock loading applications.

|

|

| |

|

- One board for Reefer & Dry Van Trailers

- Eliminates the need for two dock boards, saving time and space

Unlike an Aluminum Dock Board with legs the Model T uses two 1" stress proof pins designed to be placed in one of four positions creating the ideal lip length for both Reefer and Dry Van Trailers.

|

|

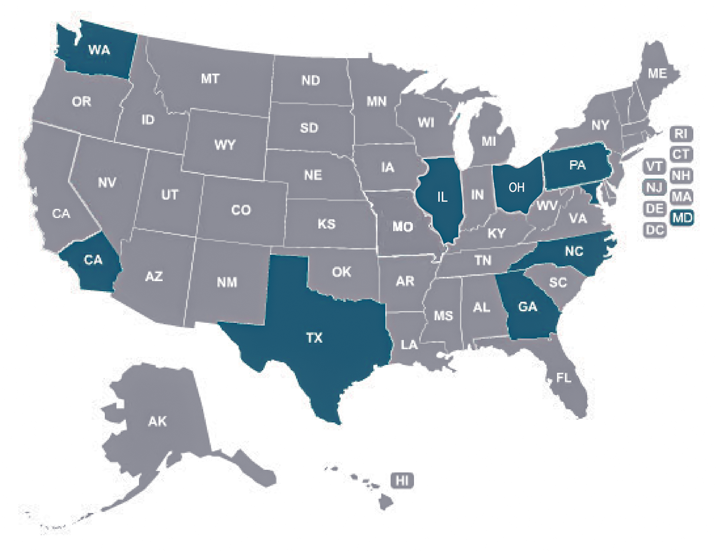

With access to a centrally located manufacturing facility and 7 quick ship locations, Loading Dock Supply offers offers extremely competitive shipping rates.

- California - Temple City

- Washington - Seattle

- Texas - Ft. Worth

- Illinois - Chicago

- Georgia - Atlanta

- North Carolina - Charlotte

- Maryland - Hagerstown

When not available at a quick ship hub all Aluminum Dock Plates ship next day.

|

|

|

|

|

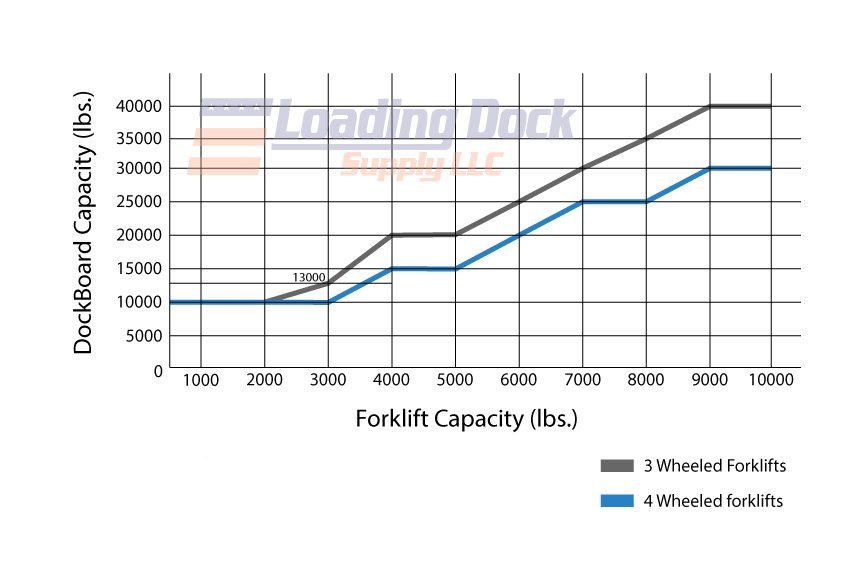

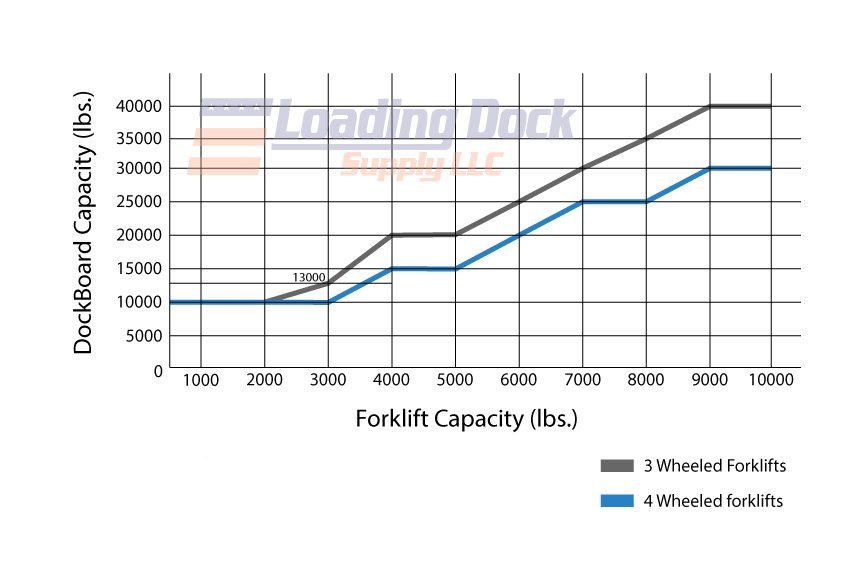

Insufficient capacity is a serious problem that severely reduces the life of your dock board, putting your equipment and personnel at risk. When determining the capacity you need consider the equipment types used and overall period of daily use.

- Match your equipment capacity rating to the increments on the bottom (x-axis)

- Follow the line up until you intersect with the block corresponding to the equipment type(s).

- Then follow the line to the left (Y-axis) to determine your recommended capacity.

- Note: operations exceeding 8 hours a day should increase their board capacity to the next level.

|

|

|

|

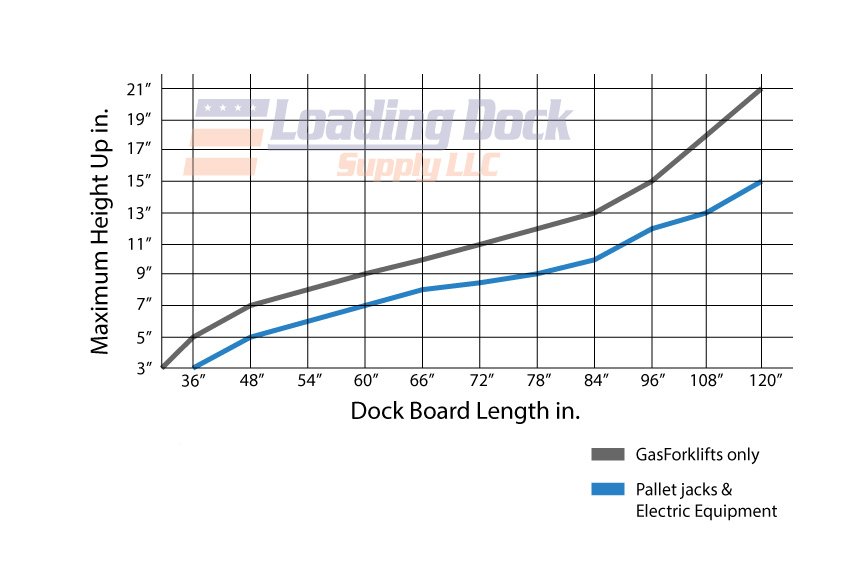

To ensure your dockboard will provide a sufficient grade for your equipment, Measure the greatest difference between dock and truck height to find the differential.

There are two variables considered in the chart below; Boards for all traffic or just gas forklifts. It is important to know what types of equipment will be using on the board to ensure the length will accommodate a 19% grade for gas forklifts or a 14% grade for everything else. Always be sure to round partial increments up.

- Match your greatest Differential to the increments on the left (Y-axis)

- Follow the line across until you intersect with the block corresponding to your equipment type.

- From there follow the line down to the Recommended board length.

|

What is the highest point a dock board can reach safely?

The longest dockboard we offer, coming in at 10' long, allows for forklifts to reach trailers up to 21" above the dock floor or all other equipment types 15" above the dock floor. For greater heights give us a call at 1800-741-1258 to discuss your options. How fast can I get one of these?

Common sizes are strategically stocked across the United States for quick shipment and short delivery times. For items not in stock we offer short lead times of 7 working days.Do you sell replacement pins?

Yes, we offer all parts and accessories for the full range of dock boards we carry. How do I move the board?

Rather than cumbersome chains the 2 pin dock board has recessed lifting loops found within the dockboards deck. Designed to flip up for easy carry and placement, via forklift, these reduce the setup time and increase stability while handling the board. What capacity do I need?

4x the carrying capacity for four wheeled equipment

3x the carrying capacity of 3 wheeled equipment

|

No account no problem, Loading Dock Supply's experts are ready to provide you with the advice and information you need regardless of whether or not you have an account. For most products, we offer freight rates and lead times over the phone or within minutes via email.

- No Account Necessary

- Immediate feedback

- Quotes are good for 30 days

- Competitive shipping rates

- Ship with us or on your own account

Give Our Dock Experts a Call 1800-741-1258

|