Dock Seals vs Dock Shelters

Key Differences

Dock Seal and Dock Shelter Specifications

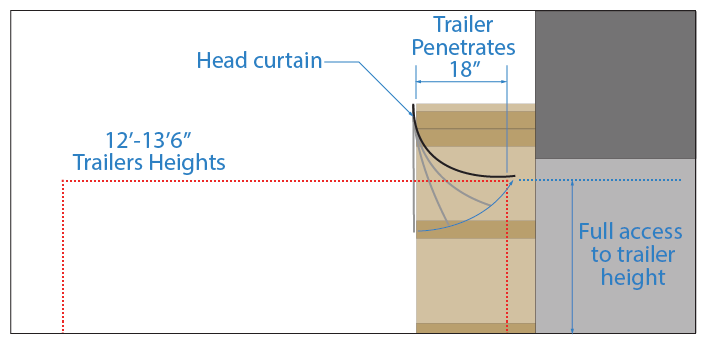

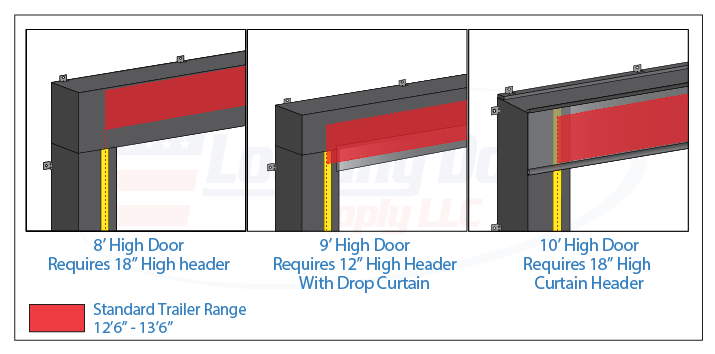

How Dock Seals & Dock Shelters Work

Conclusion In the majority of cases customers end up going with a dock seal due to it's superior sealing capabilities and lower initial price point. However, it is our opinion your final decision between a dock shelter and dock seal should be based on your needs. For example: dock seals are certainly cheaper at first, but they are prone to damage from forklift loads. This increases the cost of maintenance and ultimately brings the cost of a shelter and dock seal closer together as time progresses. Due to this eventual breaking even we recommend basing your decision on what your actual needs are:

These among other questions are all going to invariably lead you to one option or the other. Our goal is to provide you with the best possible solution. It's this reason we keep staff on hand to help you identify solutions and conflicts with design and use of your seals. Loading Dock Supply, LLC prides itself on being available to discuss your needs give us a call and we'll help you choose the right seal for the job 1800-741-1258. | ||||||||||||||||||||||||||||||||||||

sales@loadingdocksupply.com

Contact Us

1-800-741-1258

Loading Dock Equipment, Loading Dock Ramps, Dock Bumpers, Dock Boards, Yard Ramps, Dock Lights, and Industrial Equipment

Serving OH, AL, AK, AZ, AR, CA, CO, CT, DE, FL, GA, IA, IL, IN, ID, KS, KY, LA, ME, MD, MA, MI, MN, MS, MO, MT, NE, NV, NH, NJ, NM, NY, NC, ND, OK, OR, PA, RI, SC, SD, TN, TX, UT, VT, VA, WA, WV, WI, WY

Loading Dock Equipment